Because the RAP elements are stiffer than the. This Technical Bulletin discusses the design concepts for the structural design of strip footings supported by Rammed Aggregate PierRAP soil reinforcing elements.

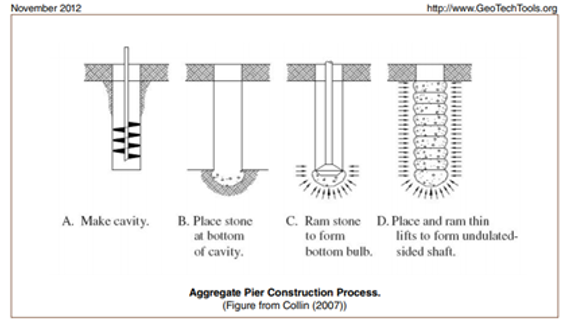

The response of an aggregate pier foundation system.

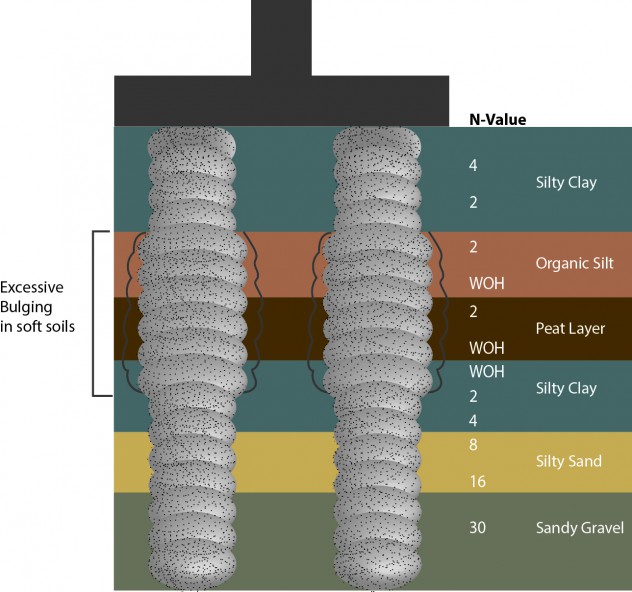

. They can be designed to meet specific improvement criteria and alternative methods of installation provide potential cost savings. The Geopier X1 system creates Rammed Aggregate Pier RAP elements using a vertical ramming process which is a combination of both replacement and displacement methods. Soft silts and clays.

The process allows for construction flexibility and the ability to construct through caving zones that are encountered during drilling operations. Soils below the groundwater table. 4453 the rebound load increments shall be held for a minimum of 5 minutes.

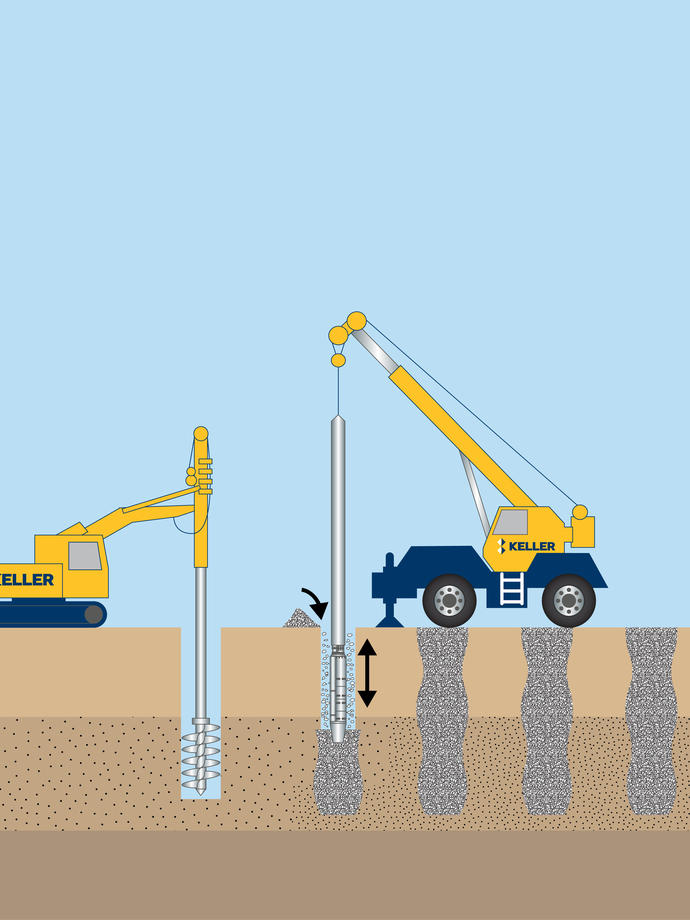

Impact hammer After driven to full depth mandrel is raised up 3 ft Then driven back down 2 ft Dense 1 ft lifts Crowd. Geopier Impact Rammed Aggregate Piers RAPs are a versatile ground improvement solution designed to reinforce poor soils through the use of a patented displacement mandrel. The down-hole compactive device may be either a high-frequency vibratory probe or a vertical tamper.

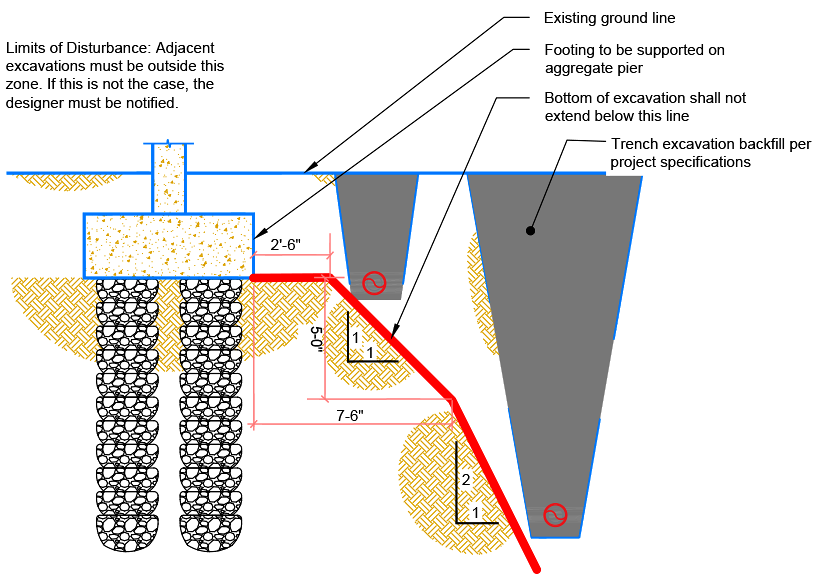

The rankine passive earth pressure coefficient is calculated for the matrix soil and multiplied by the vertical effective stress to determine the. Higher friction angles provide greater pier capacity which means fewer Geopier elements are required. Aggregate piers often work best with soils that contain soft clays silts or man-made fills.

Geopier X1 piers are constructed using a track-mounted auger to drill out unsuitable soils and a specialty mandrel mounted to a mast rig to construct the Rammed Aggregate Pier RAP elements. Principals in our firm are licensed Geotechnical engineers with extensive prior experience in Geotechnical analysis and design including 25 years of designbuild experience of the Geopier Rammed. Rammed Aggregate Pier Construction.

Then as hollow mandrel is raised stone flows from hopper down through mandrel. The piers are installed to reinforce the poor soils at a pier spacing that typically ranges between 8 and 15 feet on-center. Higher friction angles provide greater pier capacity which means fewer Geopier elements are required.

Aggregate pier installation is a ground improvement technique that constructs dense columns of compacted stone. Geopier Rammed Aggregate Pier Installation Cost. The Rammed Aggregate Pier elements shall be designed using a Rammed Aggregate Pier stiffness modulus to be verified by the results of the modulus test described in Section 502.

Typical Process Aggregate pier systems are fairly simple in nature to install. It is important that a structural engineer understand the installation and. Chance Products Are Dependable Reliable Easy to Use.

The specialty mandrel and larger equipment allows for significantly faster and cheaper pier construction. The RAP modulus is measured by full scale load testing at the project site see Fig. Rammed aggregate piers design From highlighters to doughnuts unicorn every little thing is arguably among the most significant millennial trends.

Ad Take Advantage of Saving Time Money with CHANCE Foundation Piers. The ramming process produces the superior strength of a Geopier Rammed Aggregate Pier RAP and develops constructed aggregate friction angles greater than 48 degrees almost 40 greater than those reported for stone columns. Request a Quote Today.

In addition we had 54000 of spoils removal. Ram 2 crushed rock into the bottom bulb c. Design Submittal The Installer shall submit detailed design calculations construction drawings and shop drawings the Design Submittal for review and approval at.

Ultimately we install aggregate pier. So why in the event you deprive your nails of a mystical makeover. Our company specializes in the design and construction of the GeoRam Design Engineered Aggregate Pier EAP and.

Design shall rely on subsurface information presented in the project geotechnical report. A total of 418 Rammed Aggregate Pier elements were installed in less than two weeks on site. 1 rammed aggregate pier construction process a.

In 2016 Geopier quoted 300 Rammed Aggregate Piers 28 deep 30 diameter for 387000. Essentially by using a rammed aggregate pier system to increase the existing soils bearing capacity the structural engineer can design a shallow footing system that would typically be used for a site with preferred soil conditions. Drill 30 and 33 diameter rap shafts b.

Ram ¾ to 1½ crushed road base rock in 12 lifts up to the bottom of footing plus 6 to 12 the ramming equipment consists of a 45000 pound hydraulic excavator equipped with a 3500 pound hydraulic break. Do that standout glitter design with a unicorn horn accent nail. This displacement construction method can be used in a variety of soil conditions.

The 48-hour load test plus footing cost 31000. Suited for light to heavy loads on large or small projects vibro piers are quick to install and very effective at reinforc ing the surrounding soil. The columns are installed in groups in soft soil to increase bearing pressure and mitigate settlement under structural footings.

V ibro piers also known as aggregate piers are typically in stalled to intermediate depths of 5 to 20 feet for the support of new loads. Each lift of stone or other granular material is compacted forming a high modulus aggregate pier. The modulus load test had less than 14-inch deflection at a design top-of-pier stress of nearly 17000 psf.

Provision of all equipment material labor and supervision to design and install aggregate pier elements. Contaminated soil drove the disposal cost up to 36CY. DESIGN OF STRIP FOOTINGS OVER SOIL REINFORCED BY RAMMED AGGREGATE PIERS.

Conventional strip footings supported at grade are traditionally designed assuming that the subgrade soils. Temporary casing used to stabilize caving soils. One approach for estimating the uplift capacity of rammed aggregate piers is based on lien and fox 2001 and wissman and fox 2000the lien and fox 2001 procedure includes the following steps.

The phrase aggregate piers may be used to describe either a rammed pier or a vibrated pier also called a vibro stone column VSC. The response of high modulus RAPs has been studied numerically to understand the shear and flexural behavior during seismic action. Rammed Aggregate Piers Design.

Rammed aggregate piers are an innovative and cost effected method of ground improvement. Rammed Aggregate Pier Construction. GeoBase Dynamic Subgrade Improvement.

Shear stresses from the sand to the high modulus rammed aggregate piers. Aggregate piers referenced in these specifications refer to both vibro stone columns and rammed piers. The ramming process produces the superior strength of a Geopier Rammed Aggregate Pier RAP and develops constructed aggregate friction angles greater than 48 degrees almost 40 greater than those reported for stone columns.

4452 the load increment that represents approximately 150 of the allowable rammed aggregate pier design uplift load shall be held for a minimum of 60 minutes a maximum of 4 hours and until the rate of deflection reduces to 001 inches per hour or less. Install geopier Rammed Aggregate Pier RAP elements to reinforce the compressible soils and allow for the construction of a relatively thin floor slab Figure 1d. The uplift resistance Geopeir elements had a working tension capacity of 30 kips each.

Pdf Rammed Aggregate Pier Design And Construction In California Performance Constructability And Economics Semantic Scholar

Utilities With Ground Improvement

Vibro Aggregate Piers Keller North America

Rammed Aggregate Pier Construction Process Download Scientific Diagram

Pdf Rammed Aggregate Pier Design And Construction In California Performance Constructability And Economics Semantic Scholar

0 comments

Post a Comment